Magnetic grate, hopper magnet designed exclusively for industrial use, ensures perfect cleaning of your dry mixtures from ferromagnetic impurities (by ferromagnetic impurities we mean fully magnetic metals such as iron, nickel, cobalt and iron-containing alloys, not paramagnetic, very weakly magnetic materials).

For proper function, the purified mixtures (material that you pour through the magnetic grate) must be:

- homogeneous,

- dry with good flow properties, so that the magnetic grate does not clog; see below.

This magnetic grate (hopper magnet) can also be used to separate ferromagnetic impurities from liquid mixtures. Please contact us to confirm suitability for such an application.

The magnetic grate (hopper magnet) is suitable for use only in non-continuous operations (during manual cleaning of the magnetic grate, the flow of the purified material must be stopped). It is installed only in vertical pipelines, the tubes must be horizontal, e.g. in the food and chemical industries, agriculture, waste processing, and in the production of building materials – see the list of suitable materials below (if vertical installation is not possible, do not use this product and contact us to select another magnetic grate (magnetic separator) or to confirm that it is suitable for your use)

The magnetic grate (hopper magnet) is used as a pre-stage to protect technologies so that metallic ferromagnetic impurities do not enter equipment they could damage, for example mill and crusher knives, nozzles of regranulation and granulation lines, injection molding machine nozzles, extrusion presses, pressing stations, shredding equipment, fine screens, ceramic pressing stations, glass presses, etc. It can also be used for purifying the mixture to the highest possible cleanliness, where the grate is placed at the end of the production process just before packaging and dispatch, so that no contamination by ferromagnetic metal material occurs during subsequent operations in the production plant. In this case, immediate sealing of the purified material into sealable packaging or other sealable containers is assumed. Thanks to the excellently designed magnetic circuit, a high capture rate of ferromagnetic impurities is achieved (please read the detailed description below of which ferromagnetic metal impurities this magnetic grate can capture).

The granularity (fraction, size) of the purified material may be up to a maximum diameter of 5 mm (5x5x5 mm), of regular shape; the material must be free-flowing, dry, non-sticky, and without lumps to prevent overloading (clogging) of the magnetic grate by material. By free-flowing material, as used in this description, we mean a material that, when freely poured, does not have bridging properties (clumping into solid masses), does not self-retain, and thus does not hinder free flow through the magnetic grate. Examples of such poorly flowing materials may include moist, greasy materials, as well as materials that appear dry and seemingly free-flowing but whose natural property is poor flow. An example is smooth, very finely ground flour or various very finely ground starches. Materials that we recommend and which, in our professional opinion and experience, are suitable for pouring (purification) through this magnetic grate (hopper magnet) are listed below (note the maximum permissible fraction/granularity stated above). If the material from which you require separation of metallic ferromagnetic impurities (material to be purified) is not found in the list below, do not use this product and contact us for further clarification and possible recommendation of another magnetic grate (another type of magnetic separator) or approval that this type is also suitable for magnetic separation from your material.

List of suitable materials for magnetic separation using a magnetic grate:

- granulated sugar

- powdered sugar (beware of material overloading; we recommend pouring more slowly and distributing evenly over the entire grate surface)

- cereals, various types

- lentils (with frequent use for large quantities, abrasion may occur; we warn of potentially faster wear of the protective tubes)

- crushed cocoa beans

- crushed PET bottles (beware of material overloading; we recommend pouring more slowly and distributing evenly over the entire grate surface; more suitable for smaller capacity volumes)

- rubber regranulate

- rubber crumb

- chili seeds

- animal feed, free-flowing, character similar to flour up to coarser fractions, max. granularity 5 mm (must not be abrasive)

- coconut flour

- cocoa

- flour (beware of material overloading; we recommend pouring more slowly and distributing evenly over the entire grate surface)

- poppy seeds (only poppy seeds, not whole poppy heads)

- ground corn

- meat and bone meal

- matcha powder

- pudding powder (risk of bridging and clogging; pour slowly and evenly over the entire magnetic grate)

- plastic granulate and regranulate

- plastic grind

- ash (not hot, but cooled to the operating temperature of the magnetic grate)

- food-grade bulk non-abrasive mixtures

- milk powder

- dried chocolate

- dried coconut

- dried herbs

- dried spices (finely ground or very finely crushed)

- dried instant soups

- dried whey (beware of material overloading; we recommend pouring more slowly and distributing evenly over the entire grate surface)

- sesame seeds

- glaze or glassy mass (we warn of increased abrasion and increased risk of wear-through of protective tubes)

- salt (we warn of potentially reduced service life depending on frequency of use and the material used)

- bulk starches, e.g. corn starch

- building materials (free-flowing and non-abrasive)

- tapioca pearls

We again emphasize that materials must be dry, free-flowing (must not have bridging properties), non-abrasive, with maximum regular granularity up to a diameter of 5 mm (5x5x5 mm). Throughput capacity varies depending on the material from which ferromagnetic impurities are to be separated; it cannot be clearly determined and differs for each material type. If you are unsure about throughput or capacity flow, do not use this magnetic grate; contact our technical sales department to recommend another type of magnetic separator or to approve the use of this type.

Please note that the wall thickness of the protective tube is very thin in order to achieve high magnetic induction (magnetic force) and pull-off force on its surface. Therefore, please also consider the height from which the material will be poured onto the magnetic grate (impact height). The pouring height must not exceed 1 m. This is individual for each material type and cannot be precisely specified. Pouring from excessive height may cause bending or puncturing of the protective tubes and damage to the entire product. If the height from which your material will be poured onto the magnetic grate is higher than 1 m, do not use this product and contact our technical sales department to recommend another type of magnetic separator/grate or approve use of this type.

This magnetic grate captures (separates) metallic ferromagnetic particles from a size of 1 µm and smaller (ferromagnetic character, immeasurable magnetic dust) up to approx. 5 mm (5x5x5 mm), which is the maximum fraction (size) of material that may fall onto and be poured through the magnetic grate. In exceptional cases, the magnetic grate may also capture larger metal objects up to approx. 10 mm (10x10x10 mm). However, random occurrence of these impurities is assumed to be max. 1% of the total hourly throughput capacity (regular cleaning of the magnetic grate from ferromagnetic impurities is assumed; this does not mean that the entire 1% of larger ferromagnetic impurities may remain on the magnetic grate throughout the hourly throughput). The content of these larger ferromagnetic impurities must not be higher. If the occurrence of these larger ferromagnetic impurities in your material is higher, do not use this magnetic grate and contact our technical sales department for expert consultation.

Objects larger than specified (max. diameter 5 mm, 5x5x5 mm) must not fall onto the magnetic grate, except for randomly occurring ferromagnetic impurities described above. If you are concerned about the presence of larger ferromagnetic or other impurities/additives, it is necessary to install a pre-screen with a mesh size of max. 5 mm so that these larger unwanted objects are captured before entering the magnetic grate (after installing the screen, consider reduced capacity load and throughput of the magnetic grate). The screen is not part of the magnetic grate delivery. We also warn of the possibility that your material may contain a large amount of fine metallic impurities (very fine magnetic metal dust smaller than 1 µm), which can coat the magnetic tubes and block the magnetic grate (fine magnetic particles also bind the conveyed material and overload the entire system), significantly reducing magnetic force/efficiency. If the magnetic tubes immediately become coated after starting material flow through the magnetic grate and are entirely “hidden” in iron dust, this is not a defect of the magnetic grate; it is necessary to reinforce magnetic separation with another magnetic separator/grate or clean the magnetic grate more frequently, as your material likely contains a very large amount of ferromagnetic particles.

If you are unable to ensure:

- absence of particles larger than 5 mm (5x5x5 mm) in your material

- less than 1% of larger ferromagnetic particles (up to 10 mm) in hourly capacity

- minimal occurrence of fine metallic dust in your material

do not use this magnetic grate and contact our technical sales department to recommend another type of magnetic separator or approve use of this type.

The magnetic grate (hopper magnet) is designed to capture as many metallic ferromagnetic impurities as possible. However, everything depends on the amount of such impurities present in your material. It is not possible to guarantee complete capture of all ferromagnetic impurities. It is always necessary to consider the specific technology and capacities. If required, additional types of magnetic separation/magnetic grates must be installed. Please do not rely solely on this single magnetic grate. If you are unsure, do not use this type of magnetic grate and contact our magnetic separation experts at any time.

If you place the magnetic grate into your own structure (box, hopper, chute…), note that such structures must not be made of metallic (magnetic) materials. There is a risk of injury and a significant reduction in magnetic force. All structures into which the magnetic grate is placed must be made of non-magnetic materials. The minimum distance of metallic (magnetic) structures from the magnetic grate is 200 mm.

Do not use the magnetic grate to separate stainless steel (commonly referred to as stainless), even if it appears magnetic/paramagnetic (such as after passing through various crushers or other forms of deformation; likewise, these paramagnetic stainless steels may be used to produce various screens).

The magnetic grate (hopper magnet) is not intended for magnetic separation of non-ferrous non-magnetic metals, nor for magnetic separation of components or parts that contain ferromagnetic metals (e.g. plastic parts with embedded metal residues, crushed window frames with metal strips, wooden pellets with embedded fine wires). If you need to separate such impurities as well, do not use this magnetic grate and contact our magnetic separation experts, who will advise which other magnetic separator to use or which type to add to your separation setup.

Please note that during cleaning of the magnetic grate, it is not possible to use pressurized water or immerse magnetic cores. Only a dry cloth may be used for cleaning, or well-dried compressed air to blow off residual metallic impurities and separated material.

When cleaning the magnetic grate, be very careful; the magnetic cores are very strong and can cause injury by pinching or snapping when attaching to metal objects. Do not place on anything magnetic (tables, workbenches, stair treads, floors…).

This magnetic grate is not intended for use in any environment classified as potentially explosive (ATEX).

The magnetic grate is intended for indoor use only. Do not install outdoors.

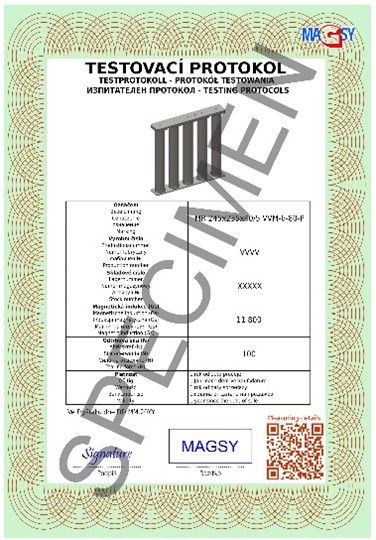

Magnetic induction measurement procedure

Measurement is carried out using a standard gaussmeter with a probe thickness of 0.75 mm at the location with the structurally highest magnetic induction – at the pole pieces or at the lowest point of the magnetic circuit arc. The test is repeated 3 times at different points of the magnetic circuit and the average magnetic induction is calculated.

Pull-off force measurement procedure

Measurement is carried out using a polished steel standard with a diameter of 10 mm and a height of 20 mm. Measurement is performed at the location with the structurally highest pull-off force – at the pole pieces or at the lowest point of the magnetic circuit arc. The force at which the standard detaches is recorded. The test is repeated 3 times and the average pull-off force is calculated.

For your information, 10 N ≈ 1 kg.

As confirmation of measurement and guarantee of measured values, we issue, and include with each delivered magnetic separator, an original measurement protocol issued specifically for your particular magnetic rod (the protocol states the stock and production number)

Operating temperature:

from -20 °C to +45 °C (from -4 to +113 °F)

Exceeding the operating temperature may be possible in certain cases; however, it is important to realize that this may lead to impaired functionality or reduced service life. In such cases, consultation with the manufacturer is required to specify the extent to which the device can be exposed to higher temperatures without damage and while maintaining safe operation.

WARNING:

The resulting pull-off force and magnetic induction depend on many factors – e.g. the dimensions of the standard, the air gap between the standard and the tested magnetic circuit, probe thickness, surface contamination, surface finish of the standard, etc. The stated values were measured under ideal test conditions. These values may vary depending on the specific environment, where operating conditions and subsequent wear may affect product efficiency and measurement results. The stated values should therefore be considered indicative, and any deviations cannot be considered a defect. To determine exact magnetic induction and pull-off force values in a specific case, individual measurement is required. If the measured pull-off force values are insufficient for you because they do not correspond to the stated values, you may use the guaranteed option to return the goods within 30 days under the conditions stated in the terms and conditions and purchase another type of magnetic separator. These 30 days are intended for product testing; after this period, the seller may refuse returns.

Copyright:

We do not agree, do not wish, and do not grant anyone permission to copy individual parts or the entire text. Modification of the text using identical phrases resulting in similar meaning and correspondence with our text is also prohibited. We do not wish and do not agree with any placement of our text on other websites, in professional journals, studies, or theses at secondary or higher education institutions without prior consent of the company Magsy. If you request use of our text or any part thereof, please contact us at any time.

Additional parameters

| Category: | Magnets for hoppers |

|---|---|

| EAN: | 8595134070187 |

| Average: | DN 100 |

| Weight (g): | 700 |

| Magnetic force on the tube: | 13.500 Gs |

| Magnetic force at a distance of 1 mm: | 8.300 Gs |

| Magnetic force in the distance. 5 mm: | 3.400 Gs |

| Material: | Stainless steel DIN 1.4301, EN 10088, (X5CrNi 18-10), ČSN 17240, AISI 304, AKV 7 |

| Breakaway force on the tube: | 95 N |

| Number of magnetic rods: | 2 |

| Surface treatment: | Glass bead blasting |

| Version: | ECO |

| Magnetic rod diameter: | 25 |

| STATUS OF PRODUCT: | New |

| Temperature resistance of the magnet: | 80 °C |

| Magnet type: | Neodym (NdFeB) |

| Suitable for the food industry: | YES |

Magnet do násypky MDN 100 SVM EKO QJN_52984

Be the first who will post an article to this item!